Imagine the exhilaration of working with state-of-the-art robotic equipment, maybe even within the cutting-edge environment of a surgical suite. You’ve devoted countless hours to training, yet you’re always mindful that even the tiniest error could lead to serious consequences. So, how can you assure absolute safety when dealing with these high-tech marvels? It’s not merely about mastering their operation, but also comprehending the integral protocols and best practices that accompany their usage. Let’s delve into the significance of routine maintenance, emergency procedures, and the indispensable role of ongoing training in this intricate field. After all, are you ready to put safety at the forefront? The tone is enthusiastic, the information is invaluable, and the appreciation for your dedication to this challenging field is immense.

In the domain of modern medicine, understanding the importance of safety protocols in robotic surgery is vital. You’re dealing with complex machines and high stakes - a slight mishap can lead to unfortunate consequences.

It’s essential to adhere to the best practices in robotic surgery. These include following the recommended robotic surgery safety protocols, such as safe use of robotic systems and strict robotic surgery maintenance. This isn’t just about being careful; it’s about being diligent, methodical, and thorough.

To minimize robotic surgery risks, it’s imperative to have extensive training for robotic surgery safety. This guarantees that you’re equipped with the knowledge and skills to handle robotic surgery equipment efficiently and effectively.

You’re about to explore the key safety procedures for handling robotic equipment. We’ll discuss regular maintenance and calibration, sterilization and infection control, and emergency shutdown protocols. These steps are critical in ensuring safety and efficiency when dealing with robotic equipment.

Regular maintenance and calibration of robotic equipment are two vital safety measures you shouldn’t overlook. These processes not only enhance the performance and longevity of your robot systems but also greatly mitigate hazards and potential accidents.

Understanding the importance of regular maintenance is essential in the context of equipment handling in robotic surgery. Like any complex machine, an industrial robot requires constant care. Neglecting routine upkeep can lead to malfunctions, posing a risk to operators and potentially compromising surgical outcomes.

Similarly, failing to calibrate your robot accurately can create safety risks. Calibration guarantees your robot operates within the defined safety standard, providing precision and consistency. Not adhering to this can result in operational errors, jeopardizing both operator safety and overall task performance.

Comprehensive robotic equipment handling training should include both maintenance and calibration procedures. This empowers you to conduct regular robotic system safety checks, reinforcing a proactive approach to risk assessment.

While handling robotic equipment, don’t overlook the critical role that sterilization and infection control play in guaranteeing safety. Adherence to best practices in sterilization and infection control can markedly safeguard both the operators and the recipients of robotic procedures.

Robotic surgery protocols emphasize the importance of sterilization as a core safety measure. This involves meticulously disinfecting robotic equipment before and after use, which can dramatically reduce risks associated with infections. Make use of appropriate sterilization techniques to guarantee the effectiveness of these safety practices.

Your safety training program must incorporate thorough modules on infection control. These modules should instruct on proper handling and disposal of biohazardous materials, as well as the use of personal protective equipment. Regular reinforcement of these practices can uphold the safety protocols in your organization.

Moreover, a proactive approach to infection control is imperative in robotic equipment handling. This means routinely inspecting your workspace for any potential infection sources and rectifying them promptly.

Shifting gears from sterilization and infection control, let’s consider another essential aspect of safety in robotic equipment handling: emergency shutdown protocols. This vital step in robot safety management is often overlooked, but it’s a significant part of ensuring safety.

Emergency shutdown protocols are safety procedures designed to stop the robot in the event of a malfunction or danger. These protocols are integral to the control system of any industrial robot system. They function as the last line of defence, halting all operations to prevent potential hazards and injuries.

Understanding and implementing these safety regulations is not just about compliance; it’s about the practical necessity of keeping your environment safe. The first step involves familiarizing yourself with the control system of the robotic equipment. You need to know how to quickly and efficiently initiate an emergency shutdown.

Safety systems, including emergency shutdown protocols, are designed to be user-friendly. However, mastery over these systems requires rigorous practice and a thorough understanding of the equipment. Remember, the goal is to stop the robot safely, minimizing any potential damage or injury. It’s a critical aspect of robotic equipment handling that demands your attention and understanding.

You’re now ready to understand the significance of training surgical teams in safe robotic operation. The first point to take into account is equipment-specific training which guarantees each team member is proficient in operating and troubleshooting the robotic equipment. In addition, we’ll discuss the importance of regular safety drills and adherence to protocols, which can drastically reduce the risk of mishaps during surgeries.

When it comes to handling intricate robotic surgical systems, proper training is paramount. It’s essential for surgical teams to have equipment-specific training to guarantee safe robot operation. A lack of in-depth understanding of the robotics can lead to incorrect usage, compromising both industrial robot safety and patient welfare.

Your training should focus on understanding the unique safety features each robotic system possesses. This involves becoming familiar with robot safety standards, and how they apply to the specific equipment you’re using. Remember, adherence to safety guidelines isn’t just about protecting the patient—it’s also about safeguarding your own safety.

Effective safety protocols demand that you not only know how to operate the robotic system but also understand the underlying principles driving its operation. This knowledge guarantees that in the event of a system error or unexpected behaviour, you’ll be well-equipped to respond appropriately, keeping safety as your primary concern.

Building on your understanding of the robotic system, it’s important to regularly participate in safety drills and adhere to established protocols. Thorough safety protocols guarantee that safety is always at the forefront of your operations. Safety drills, in particular, are essential in teaching you how to react to potential hazards and mitigate risks.

Proper safety measures should be second nature to you and your team. Regular practice of these measures guarantees that you are prepared for any situation that may arise. Adherence to safety standards is paramount in maintaining a safe environment for everyone involved.

Robotic safety is not something to be taken lightly. It’s a delicate process that requires a deep understanding of the system, a dedication to learning, and a commitment to safety. Safety is imperative, and robust safety measures need to be in place to protect you, your team, and ultimately, your patients.

Keeping a keen eye on robotic equipment can help you promptly detect any safety incidents. Monitoring is essential in maintaining thorough safety and ensuring the safety of all personnel. As part of best safety practices, you should vigilantly observe the operation of robotic equipment to detect any irregularities or deviations from industry standards.

Reporting safety incidents is equally important. If an incident occurs, you need to report it immediately to the Occupational Safety and Health Administration. This allows them to investigate and take necessary measures to prevent similar incidents in the future. It also contributes to improving workplace safety as a whole.

You should always be aware of safety concerns when handling robotic equipment. Stay updated with the latest safety technologies and use them to enhance your monitoring capabilities. Remember, diligence in monitoring and reporting not only maintains safety but also helps shape future industry standards. By following these guidelines, you’ll be playing an integral role in upholding workplace safety and promoting a culture of responsibility and accountability.

Looking towards the horizon of technological advancements, the future of robotic surgery safety protocols holds immense potential. Key enhancements will be driven by cobots, or collaborative robots, that are designed to work seamlessly with humans in a shared work environment. These robots are built with built-in safety features that guarantee robot safety, adhering to industry best practices.

You’ll see significant strides in the implementation of cobots in surgical procedures, especially in the field of occupational safety. Cobots are equipped with advanced sensory technology, which allows them to react in real-time to their surroundings. This feature aids in reducing the risk of injury in the workplace.

Furthermore, the future also holds the promise of more intelligent collaborative robot applications. Robotic technology will continue to evolve, leading to robots that can learn from their environment and adapt their operations accordingly.

These future enhancements won’t just improve occupational safety, but they will also revolutionize the way surgeries are performed. So, as you continue to implement robotic technology in your operations, rest assured that the future of robotic surgery safety protocols is bright, with a stronger focus on collaborative, adaptive, and safer operations.

Steering through the sphere of robotic equipment handling and its safety protocols may seem intimidating at first. However, as you explore deeper, you’ll uncover a thorough area that prioritizes safety above all. You’ll understand the safety concerns associated with the use of industrial robots and how you can maintain robot safety by adhering meticulously to standards for the robotics industry. There are specific practices to evaluate in order to guarantee effective safety. Primarily, you need to comprehend the safety requirements specific to your robotic system. Recognize that technology and safety are not mutually exclusive—instead, they work hand in hand to facilitate safer, more efficient operations. At Dr. Brian Harkins, we are committed to advancing safety alongside technological excellence.

Sensors are crucial for identifying potential hazards in robotic systems. They can detect changes in the work area and stop a mobile robot if a risk is present, maintaining a safe work environment for both humans and robots.

Compliance with American National Standards set by the American National Standards Institute helps establish practices for industrial robots that ensure that safety is prioritized in every phase of the system’s operation.

Light curtains create a barrier around the robot work areas, stopping a robot automatically if the barrier is breached. This safety feature is part of comprehensive safety protocols in environments where humans and robots interact.

ISO standards define essential requirements for industrial robot safety, covering every aspect of robots and robot systems. Adhering to these standards ensures a comprehensive safety approach, minimizing risks in hazardous conditions.

Key practices to consider include using safety mats, defining safe work environment protocols, and regularly identifying potential hazards. This approach ensures an environment that minimizes risks for humans and robots.

Automation in robotic systems requires stringent comprehensive safety protocols to prevent accidents. Robots and robot systems must be tested for safety to allow efficient interaction between humans and robots without compromising security.

Safety mats detect pressure and deactivate systems if someone steps into a robot work area, reducing risks associated with industrial robots and ensuring a safe work environment.

Identifying potential hazards allows for early intervention in a hazardous work area. This proactive approach ensures comprehensive safety protocols are in place and minimizes risks in environments where humans and robots operate together.

The International Federation of Robotics promotes best practices and safety standards globally. Their insights help establish protocols for safe operation, particularly in environments where robots operate alongside humans.

The key aspects of robot safety in shared environments include comprehensive safety measures like light curtains, safety mats, and adherence to standards for robotics. These measures help create an environment where humans and robots can work together safely.

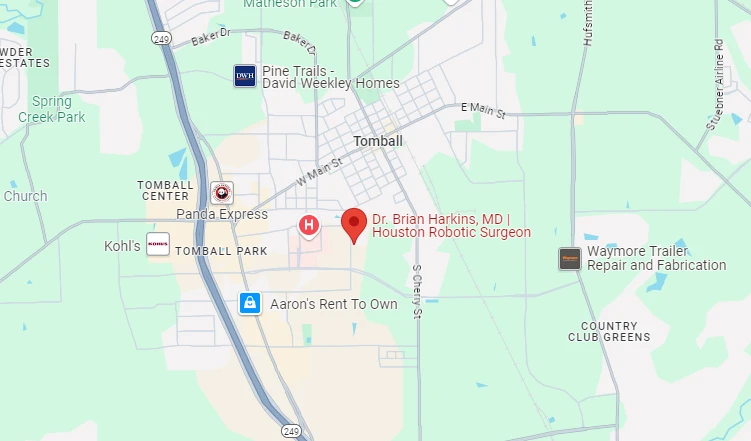

Dr. Brian Harkins is a renowned surgeon specializing in advanced, minimally invasive, and robotic surgical techniques. With a dedication to innovation and personalized patient care, he has transformed countless lives by delivering exceptional outcomes.

I want a website like this, where do i start?