Welcome to a fascinating era where robots are progressively becoming an integral part of our everyday lives, especially in the medical field. As we gradually transition towards full automation in surgical procedures, it’s an opportune moment to appreciate the marvels of technology and ponder: Can we entrust these robotic systems with absolute confidence? Indeed, these advanced machines are engineered to deliver precision and speed beyond human capabilities, but can they genuinely handle the intricacies of complex surgeries autonomously? Let’s not overlook potential challenges, from technical hiccups to ethical dilemmas. However, should we view this as a hasty leap into an unknown future, or as an exhilarating stride into a new frontier of medical technology? Let’s delve into this captivating topic.

You’re probably aware that robotic systems are increasingly used in surgical procedures, but you might be surprised by the extent of their capabilities. Let’s first look at the different levels of automation in robotic surgery and how they enhance precision and control. Then we’ll move on to discussing the variety of procedures that are currently being assisted by robots, potentially revolutionizing healthcare.

Delving into the domain of automated robotic surgery, we encounter a spectrum of capabilities that these advanced systems bring to the operating table. Robotic surgery advancements have moved us from assistance-based surgery to fully automated robotic surgery. This automation in robotic surgery presents both exciting possibilities and unique challenges.

At one end of the spectrum, we’ve got robotic surgery without human assistance. These autonomous surgical robots rely on AI in robotic surgery to perform intricate operations, promising increased precision and decreased human error. However, the full realization of this technology is stymied by robotic surgery safety concerns and challenges in surgical automation. Can we trust automated healthcare robotics to the extent of completely removing the human element from the equation?

At the other end, we have systems that require human control but offer assistance in the form of stability and precision, a step up from traditional surgery. The robotic system reliability in these cases is undeniable, but we’re still reliant on the human surgeon’s skill.

Stepping into the domain of current capabilities, robots are already making a significant impact in various surgical procedures. These applications of robotics systems have changed the way you might think about the traditional operating room.

The robot’s precision and control have proven beneficial in procedures like prostatectomies, gynecological surgery, and cardiac valve repair. Working with robots, surgeons can perform complex tasks with enhanced vision, precision, and control. The reliability of robotic surgery is not just about avoiding human error; it’s about enhancing capabilities and patient outcomes.

Automated surgical systems are particularly adept at minimally invasive procedures. This means smaller incisions, less blood loss, and quicker recovery times for patients. The future of medical robotics looks promising, as research is underway to expand the scope of robotic-assisted surgical procedures.

The reliability of a robotics system in a surgical setting is essential. As the technology evolves, so too does the need for stringent checks and balances. This calls for continuous advancement in the design and operation of these systems. With the current state of medical robotics, we’re on the cusp of a new era in surgery, brimming with untold potential.

You’re now entering the tricky terrain of achieving full automation in robotic systems. It’s not just about overcoming technical limitations, but also addressing safety and reliability concerns. On top of that, you can’t ignore the inevitable ethical and regulatory considerations that come into play.

How can we achieve full automation in robotic systems? The answer is complicated by the technical limitations of robotic systems. These limitations pertain to hardware and software, system design, and the ability to troubleshoot potential failures.

The future of robotic automation hinges on overcoming these challenges. The system design is often complex and requires sophisticated programming and engineering. The smallest error can cause performance hitches, or worse, full-blown system failures. The overall performance of a robotic system, as a result, is only as robust as its weakest component.

Potential failures are another significant hurdle. Robots are machines after all, and like any machine, they are prone to wear and tear. The ability to predict and troubleshoot these failures is essential to maintain the system’s performance.

Lastly, the need for human intervention remains a significant limitation. Despite advances in technology, there is no robotics system that can operate independently in all scenarios. Human intervention is still necessary to manage unexpected situations and to enhance the performance of robotics systems.

While working towards full automation in robotic systems, you can’t ignore the safety and reliability concerns that present significant challenges. Reliable robotics are essential for industrial automation to minimize downtime and guarantee smooth operations. High safety standards and stringent system requirements are critical for the future of robotics.

Imagine a robotic system that fails frequently. This not only hampers productivity, but it also poses safety risks. Automation is only as good as its reliability. A single mishap or system failure could lead to devastating consequences, especially in sectors such as healthcare or manufacturing where precision is key.

Therefore, it’s important to incorporate robust maintenance practices to prevent system failures and increase the reliability of the robotic systems. Regular checks and timely updates can help spot potential issues before they escalate, reducing downtime and increasing safety.

In the quest for full automation, it is vital to traverse a maze of ethical and regulatory considerations. You’re not just creating an autonomous system; you’re steering through a universe where robotics and automation often outpace the laws that guide them. It’s a complex process, but it’s far from impossible.

You’ll need to reflect on the potential implications of artificial intelligence on the entire system, and how it could impact human lives. This goes beyond automated testing and into the domain of decision-making without human intervention. How will the system handle unforeseen situations? What are the consequences if things go wrong? These ethical considerations are significant for any management system.

Additionally, you’ll need to maneuver through the legal landscape. The field of robotics technology is evolving so rapidly that laws often struggle to keep up. You’ll need to guarantee seamless collaboration between humans and machines while adhering to the current regulations.

Now, let’s shift your focus to the steps toward achieving full automation in surgical robotics. The key steps include the integration of artificial intelligence and the ability to process and analyze data in real-time. Understanding these steps will give you a clearer picture of how surgical robotics are evolving to achieve full automation.

The world of surgical robotics is on the cusp of a revolution, one driven by the integration of Artificial Intelligence (AI). AI’s algorithmic prowess and data analytics capabilities are rapidly transforming robotics applications, especially in the field of industrial robotics and automation systems.

The integration of AI into robotics isn’t just about embedding smart algorithms into machines. It’s about creating collaborative robots, or ‘cobots’, that can learn from and interact with their human counterparts. These cobots use AI to improve their decision-making processes, enhance their vision systems for better navigation and precision, and even predict potential system failures before they occur.

Moreover, the advent of the Internet of Things (IoT) has further propelled the integration of AI in robotics. IoT devices provide a wealth of data that AI can analyze and learn from, leading to continuous improvements in robot performance and reliability.

With advancements in AI and the IoT creating smarter, more reliable robots, another key development is taking shape: real-time data processing and analysis. This transformative tech is the backbone of automation and robotics. It allows for quick, accurate decisions based on real-time sensor data, critical for the operation of mobile robots.

As a robotics engineer, you’ll integrate these systems. You’ll leverage data analytics to predict possible outcomes, making robots more reliable. This predictive power improves the accuracy of robots, reducing errors. Real-time processing also boosts productivity and efficiency, as robots can adapt to changes instantly.

Yet, it’s not just about quick calculations. It’s also about making sense of vast quantities of data. Here, real-time analysis comes into play. By analyzing data as it comes in, you can identify patterns and trends faster, refining your robotic systems on the fly.

Imagine a world where robotic systems perform surgeries with such precision and efficiency that human error is practically eliminated. This isn’t a far-off concept; it’s a cutting-edge reality in the field of robotics. The future directions of automation in robotic surgery are set to optimize surgical procedures, raising the bar for medical treatment.

The architecture of these robotic systems is being constantly refined, enhancing the functionality that service robots can offer. The capabilities of robots have evolved to adapt to changing circumstances, making them a powerful ally in complex medical procedures. These robotic systems can help streamline operations, offering an unmatched level of precision that can lead to improved patient outcomes.

Technological developments have paved the way for an exciting future in the automation of robotic surgery. It’s critical to understand that these advancements aren’t intended to replace human surgeons but to enhance their ability to deliver top-quality healthcare. It’s a future where man and machine work together, complementing each other’s strengths. With continuous improvements in technology, we’re moving closer to a world where the precision of robotic surgery becomes the norm rather than the exception.

In the grand scheme of things, you’re at the forefront of a revolutionary shift in healthcare. Robotic system reliability continues to evolve, holding the potential to improve patient outcomes and fundamentally change how surgeries are conducted.

Full automation is an ambitious goal, but not unreachable. It requires systems to accommodate and adapt to new surgical techniques, complex medical conditions, and unexpected patient reactions. The need for reliable, robust systems is vital to minimize downtime and guarantee consistent, high-quality care.

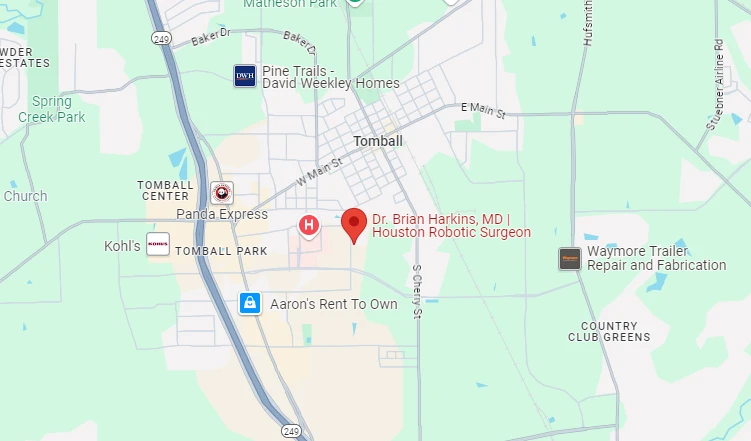

The performance over time of these systems is essential. As they learn and adjust, their reliability should increase. It’s not just about maintaining a stable operating environment – it’s about enhancing it. It’s about building systems that can learn from their mistakes, improve their capabilities, and consistently provide the highest level of care. At Dr. Brian Harkins, we are dedicated to leading this transformation, ensuring that our patients benefit from the most advanced and reliable robotic systems in healthcare.

Engineering and robotics play a crucial role in modern manufacturing by optimizing factory automation, improving system performance, and enhancing productivity through robots operating alongside humans.

Businesses can proactively schedule preventive maintenance, assess areas for improvement, and integrate solutions related to the robot to minimize downtime and ensure consistent performance.

Six-axis robotic arms are versatile robotic solutions that allow precise and flexible movements, enhancing factory automation and enabling robots to operate in complex manufacturing tasks.

Within industry 4.0, robots work by seamlessly integrating with data-driven systems, providing scalable solutions, and enhancing interactions between humans and robots for optimal performance.

Organizations should invest in robotics integration, conduct regular deployment reviews, and implement solutions that meet industry-specific needs to ensure their robots operate efficiently.

Robots need continuous adaptation, such as upgrades in robotics integration and new technologies, to meet user-specific requirements and respond to changing industry demands.

The IEEE International Conference explored how robots are making transformative impacts in industry 4.0, focusing on scalable solutions, factory automation, and emerging areas for improvement.

The deployment of robots automates repetitive tasks, enhances precision, and allows for solutions that meet complex manufacturing needs, boosting overall productivity and efficiency.

Ensuring seamless collaboration between humans and robots involves addressing safety protocols, optimizing system performance, and fostering relationships that could enhance workflow efficiency.

Using robots for high-pressure tasks involves balancing pressure to deliver cutting-edge results with proper deployment strategies, ensuring reliability and minimal downtime and ensuring consistent output.

Dr. Brian Harkins is a renowned surgeon specializing in advanced, minimally invasive, and robotic surgical techniques. With a dedication to innovation and personalized patient care, he has transformed countless lives by delivering exceptional outcomes.

I want a website like this, where do i start?